Beyond the immediate financial repercussions, downtime can erode the trust and confidence that manufacturing organizations have painstakingly built with their customers over time. In an era where reliability and timeliness are non-negotiable aspects of customer satisfaction, any disruption in service can tarnish a company’s reputation.

For manufacturing firms, especially those operating in industries with stringent quality standards like automotive, aerospace, or pharmaceuticals, even a minor hiccup in production can lead to significant consequences. Customers rely on these organizations to deliver goods consistently and on schedule, often as part of complex supply chains where delays can have far-reaching implications.

Moreover, in today’s interconnected digital landscape, news of downtime incidents can spread rapidly through social media and industry forums, amplifying the negative impact on brand perception. Understanding this, manufacturing organizations must not only focus on minimizing downtime but also invest in effective communication strategies to manage the fallout when disruptions inevitably occur.

Downtime represents a multifaceted challenge for manufacturing organizations, requiring a holistic approach that combines technological innovation, operational efficiency, and proactive risk management to safeguard both productivity and reputation.

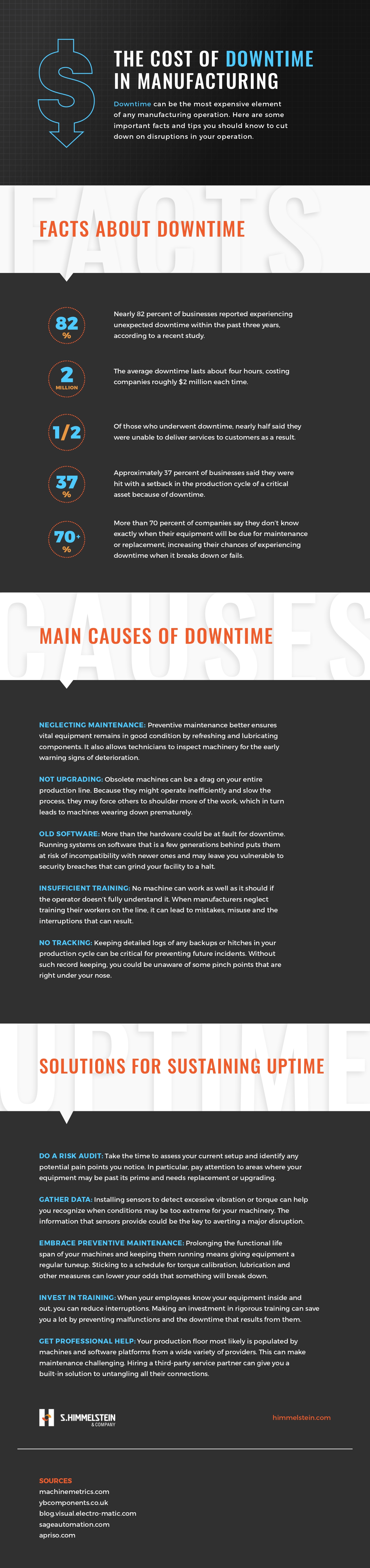

For more information on how organizations are attempting to limit instances of downtime across their operations, please check out the infographic included alongside this post.

The Cost Of Downtime In Manufacturing, provided by S Himmelstein and Company, the organization to shop with for your next torque transducer